Contact Us

E-mail: yilin@cn-tsjsrs.com

WhatsApp: +86 18731531256

Address: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Products

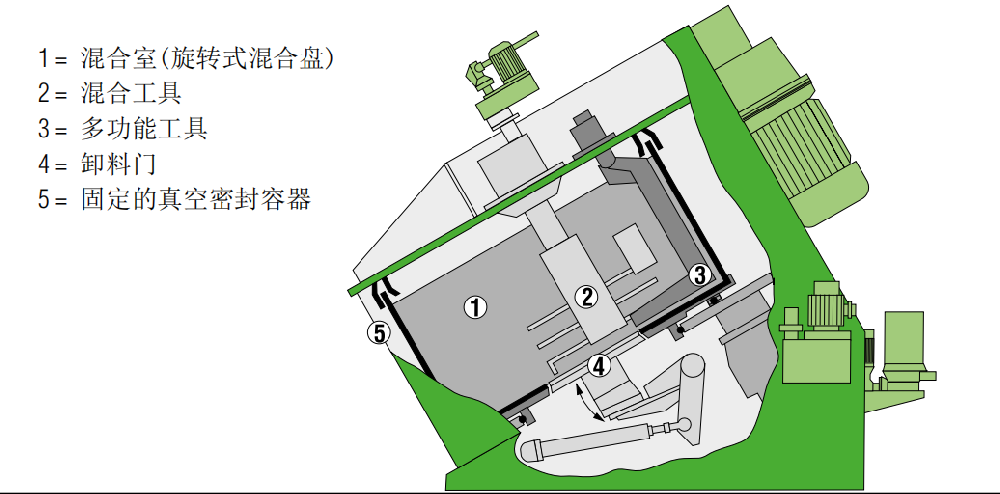

1-Mixing chamber (rotating mixing disc) ,2- Mixing tool,3- Multi-function tool, 4- Discharge door,5- Stationary vacuum seal container

Compatible with a wide range of fuels, it can be used to manufacture hot air furnaces fueled by blast furnace gas, coke oven gas, converter gas, mixed gas, producer gas, natural gas, liquefied petroleum gas, chemical waste gas, heavy oil, diesel, and pulverized coal.

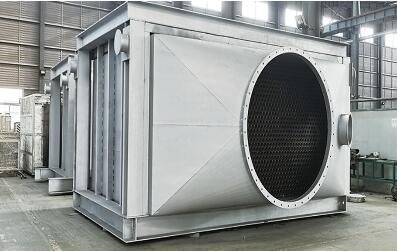

Air-to-Air Plate Heat Exchanger

The air/air plate heat exchanger uses metal corrugated plates as heat transfer elements and is sealed using a welding process, which greatly improves the safety and reliability of the heat exchanger. It has the characteristics of high heat transfer coefficient, low pressure drop, and small footprint. It is a new type of high-efficiency heat exchange equipment.

Air-to-Air Tube Heat Exchanger

The air to air tube heat exchanger consists of a shell, heat transfer tube bundles, tube sheets, baffles, and insulation layers.

In a cyclic operation, the three processes of feeding, mixing, and unloading are performed at regular intervals, i.e., mixing is done in portions. Because all materials are accurately weighed, the mixing quality is excellent. This type of operation is currently the most widely used.

Horizontal Intensive Mixing Mixer

A horizontal intensive mixer features a high-strength agitator shaft with plowshare-shaped agitator blades arranged along different spiral lines. The blades within the horizontal cylinder rotate with the main shaft, causing the material to turbulently move radially along the cylinder arm. The material then flows through the agitator assembly, where it is scattered by the high-speed rotating agitator blades. This continuously folds and recombines the material, achieving uniform mixing in a short period of time. The inclined ends of the agitat

A twin-shaft mixer is a mixing and conveying device featuring spiral blades arranged on two parallel, symmetrical axes. Once material enters the mixer through the feed port, the two parallel, symmetrical axes rotate in opposite directions, continuously stirring and mixing the material under the action of the spiral blades.

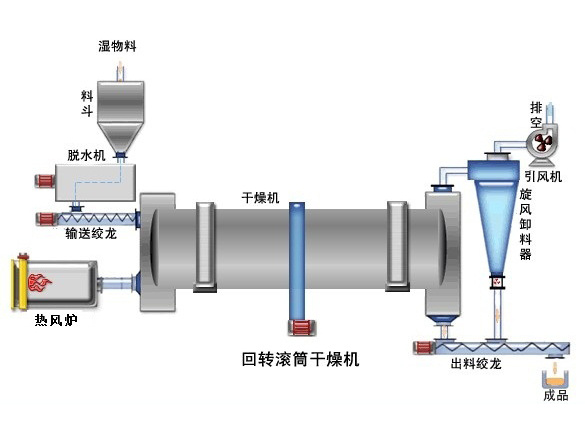

It is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring.

Drum Drying MachineThe drum dryer is one of the traditional drying equipment, with reliable operation, high flexibility and adaptability, large processing capacity, diameter: medium1000-mid 4000, length determined by drying requirements.The cylinder dryer mainly consists of parts such as the revolving body, the ballast plate, the drive unit, the support unit and the sealing ring. The dryer is a cylinder slightly inclined to the horizontal direction, the material is added from the higher end, the hot flue gas and the material flow into the cylinder, and as the cylinder rotates, the material runs to the lower end due to the action of gravity. A sweep plate is installed on the inner wall of the cylinder, which scoops up the material and drinks it, so that the contact surface of the material with the air flow is increased to increase the drying rate and promote the material forward. After drying, the product is collected from the bottom and bottom.

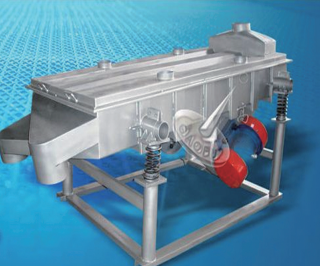

The vibration filter works by using the forward spin generated by the oscillation of a vibrator. The upper rotating hammer of the oscillator causes the screen to produce a plane-oriented rotation vibration, while the lower rotating shock causes a cone-oriented vibration, and the effect of its combined action causes it to produce circular vibration.Its vibration trajectory is a complex spatial curve. This curve projects as a circle on the horizontal plane and an ellipse on the vertical plane. Adjusting the excitation force of the upper and lower rotating weights can change the amplitude.And by adjusting the spatial phase angle between upper and lower weight hammers, the curve shape of the screening surface trajectory can be changed, as well as the motion trajectory of material on the screen.

Hammer crushers are suitable for crushing medium-hard materials such as limestone, slag, coke, and coal in industries such as cement, chemical engineering, power generation, and metallurgy. They perform intermediate and fine crushing operations on these materisleComposition: It consists of a hammer crusher housing, rotor, hammer head, counterattack liner plate, screen plate, etc.Work principle: The hammer crusher mainly relies on impact energy to complete the crushing of materials. When the hammer crusher is operating, the motor drives the rotor to a high speed rotation, the material enters the cavity of the crusher evenly, and the high speed turning of the hammer head hits,cuts and tears the material, causing the material to be broken. At the same time, the gravity of the material itself causes the material to rush from the high-speed rotating hammer head to the internal panels and screens in the frame, and materials greater than the size of the screen are blocked on the screen plate and continue to be hit and grinded by the hammer until they are crushed until the required particle size is finally excreted through the screen plate.

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.