Operation method:

Cyclic operation

Description:

In a cyclic operation, the three processes of feeding, mixing, and unloading are performed at regular intervals, i.e., mixing is done in portions. Because all materials are accurately weighed, the mixing quality is excellent. This type of operation is currently the most widely used.

Continuous operation:

The continuous operation method involves the three steps mentioned above being carried out continuously within a relatively long cylinder. Although its productivity is higher than that of the cyclic operation method, the mixing quality is poor due to the difficulty in controlling the mixing ratio of the various materials and the mixing time. Currently, it is rarely used.

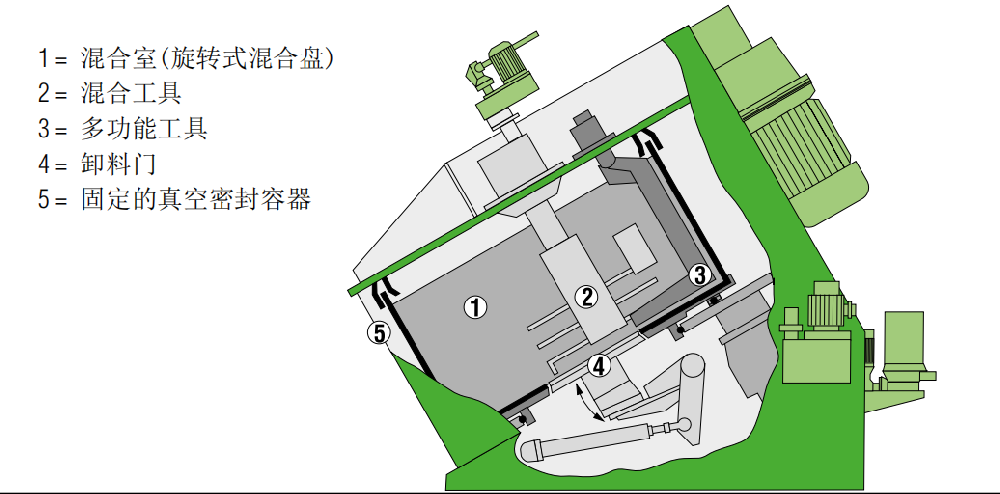

1 - Mixing chamber (rotating mixing disc) 2 - Mixing tool 3 - Multifunctional tool 4 - Discharge door 5 - Fixed vacuum seal container

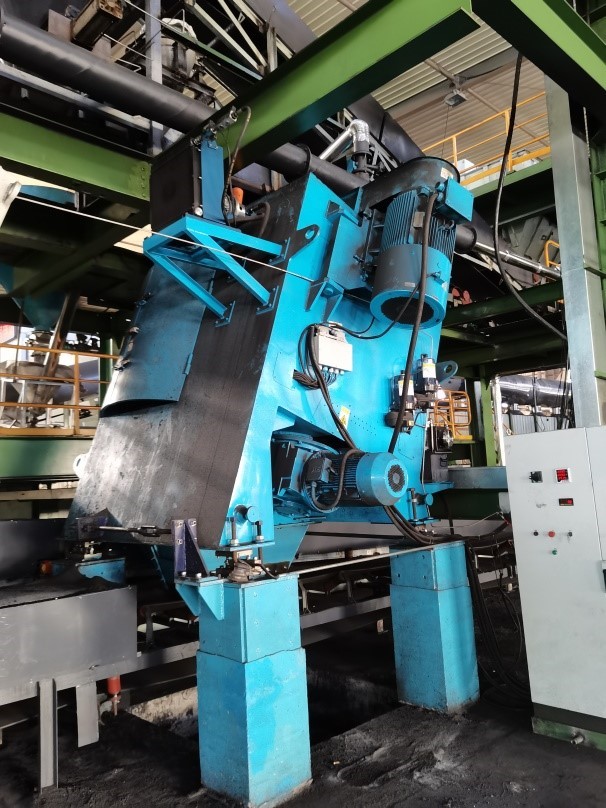

The 3D high-efficiency mixer utilizes a multi-dimensional mixing method. The mixer body is arranged at an angle, with the mixing rotor eccentrically positioned within the mixing drum. The drum rotates, conveying the material to the high-speed rotating rotor area. Side scrapers are installed within the mixer to strip material from the drum wall while simultaneously draining the material, flipping the material for macro-mixing, and then pushing the material toward the mixing rotor. Furthermore, the tilted installation of the rotating mixing drum creates a strong vertical downward component of the mixture flow at its highest point, causing the material to scatter into the mixing rotor area, where the circulating material flow is agitated by the rotor. By combining multiple mixing methods, a subtle and thorough mixing effect is achieved within the complex flow of mixed materials.

Features:

1. High production efficiency and excellent mixing uniformity: The multi-dimensional mixing method generates powerful power in a short period of time to achieve thorough mixing of materials.

2. High equipment reliability and minimal internal wear: The bottom and walls of the mixing drum are equipped with wear-resistant alloy liners, and the mixing rotor blades and side/bottom scrapers are inlaid with wear-resistant carbide mixing tools for durability.

3. Easy maintenance: The mixer is equipped with an observation window on the top, allowing customers to observe the mixing process and the internal conditions of the mixing drum. The mixing drum is equipped with a hinged inspection door for maintenance and replacement of spare parts. The wear-resistant liners on the mixing drum walls and bottom are individually removable and replaceable, and the mixing rotor blades are designed to be separated from the rotating shaft for easy replacement. 4. Diverse Drive Types: The mixer's power requirements, speed, and energy transmission method can be selected based on the specific preparation task. A variety of drive types are available: a. The main mixing rotor is driven by a standard variable frequency motor and V-belt. This configuration offers a simple structure and easy maintenance, but has poor power transmission performance. b. The main mixing rotor is driven by a standard variable frequency motor and gearbox. This configuration is highly stable and reliable.

5. Fast Discharge, Shortening Mixing Time: The discharge port is located at the center of the bottom of the mixing drum and uses a hydraulic drive. At the end of the mixing cycle, sidewall/bottom scrapers move material remaining on the bottom and edges of the mixing drum to the center of the mixing drum, facilitating quick discharge.

6. Convenient Operation and High Level of Automation: PLC-based overall control communicates with the production line for automatic feeding and discharging. Mixing time can be adjusted online. Material level monitoring is achieved using a level meter and load cell. A centralized lubrication system automatically replenishes mechanical components according to set lubrication schedules, and a hydraulic discharge system ensures automatic discharge. The system also features safety interlocks such as speed monitoring and door opening interlocks.

7. Diverse Structures: To accommodate the mixing of certain viscous materials, small mixers can be designed with a lift-up top cover and a tilting mixing drum to ensure smooth material discharge.

8. Comprehensive Supporting Auxiliary Equipment: The mixer can be equipped with an optional dust collector to ensure dust-free mixing.

9. Wide Range of Applications: Suitable for a variety of industries requiring uniform mixing, including building materials, metallurgy, and refractory materials.

Equipment parameter table:

model | QB11 | QB12 | QB15 | QB19 | QB22 | QB24 | |

Mixing cylinder | diameter | 1100 | 1200 | 1500 | 1900 | 2200 | 2400 |

Drive motor/kw | 7.5 | 11 | 15 | 22 | 37 | 45 | |

Stirring rotor | diameter | 580 | 650 | 700 | 900 | 1000 | 1100 |

drive motor/kw | 22 | 37 | 45 | 90 | 132 | 160 | |

Throughput | L | 150 | 300 | 500 | 1000 | 1500 | 2000 |

KG | 250 | 400 | 650 | 1500 | 2000 | 2500 | |

Number of stirring shafts |

| 1 | 1 | 1 | 1 | 1 | 1 |

Keywords

Download

3D Mixer

Contact Us

Classification:

Case Introduction

3D Blender Site Map

3D Blender Site Map

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.