Contact Us

E-mail: yilin@cn-tsjsrs.com

WhatsApp: +86 18731531256

Address: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Reduction and reutilization technology of powder bonded cold solidified pellets

The flap dryer is a drying machine based on the principle of bidirectional conveying.

The mesh belt dryer is a batch and continuous production drying equipment that uses electric heating, steam heating, and hot air heating to carry materials for continuous drying using a steel mesh as a conveyor belt.

The high-pressure briquetting machine consists of two facing, synchronously rotating extrusion rollers: one fixed and one movable. The material is forcibly pressed in by a pre-pressing screw above it, then continuously drawn between the rollers by the press rollers and into the ball trough.

Drum Drying MachineThe drum dryer is one of the traditional drying equipment, with reliable operation, high flexibility and adaptability, large processing capacity, diameter: medium1000-mid 4000, length determined by drying requirements.The cylinder dryer mainly consists of parts such as the revolving body, the ballast plate, the drive unit, the support unit and the sealing ring. The dryer is a cylinder slightly inclined to the horizontal direction, the material is added from the higher end, the hot flue gas and the material flow into the cylinder, and as the cylinder rotates, the material runs to the lower end due to the action of gravity. A sweep plate is installed on the inner wall of the cylinder, which scoops up the material and drinks it, so that the contact surface of the material with the air flow is increased to increase the drying rate and promote the material forward. After drying, the product is collected from the bottom and bottom.

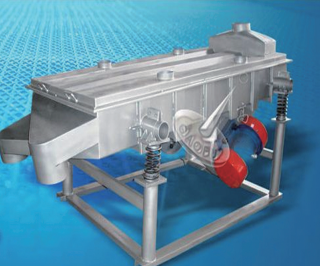

The vibration filter works by using the forward spin generated by the oscillation of a vibrator. The upper rotating hammer of the oscillator causes the screen to produce a plane-oriented rotation vibration, while the lower rotating shock causes a cone-oriented vibration, and the effect of its combined action causes it to produce circular vibration.Its vibration trajectory is a complex spatial curve. This curve projects as a circle on the horizontal plane and an ellipse on the vertical plane. Adjusting the excitation force of the upper and lower rotating weights can change the amplitude.And by adjusting the spatial phase angle between upper and lower weight hammers, the curve shape of the screening surface trajectory can be changed, as well as the motion trajectory of material on the screen.

Hammer crushers are suitable for crushing medium-hard materials such as limestone, slag, coke, and coal in industries such as cement, chemical engineering, power generation, and metallurgy. They perform intermediate and fine crushing operations on these materisleComposition: It consists of a hammer crusher housing, rotor, hammer head, counterattack liner plate, screen plate, etc.Work principle: The hammer crusher mainly relies on impact energy to complete the crushing of materials. When the hammer crusher is operating, the motor drives the rotor to a high speed rotation, the material enters the cavity of the crusher evenly, and the high speed turning of the hammer head hits,cuts and tears the material, causing the material to be broken. At the same time, the gravity of the material itself causes the material to rush from the high-speed rotating hammer head to the internal panels and screens in the frame, and materials greater than the size of the screen are blocked on the screen plate and continue to be hit and grinded by the hammer until they are crushed until the required particle size is finally excreted through the screen plate.

This model is suitable for medium and fine crushing operations of non- metallic materials with compressive strength not exceeding 140 MPa, widely used in steel,, power, chemical industry, building materials departments,especially applicable to sintering plants and carbon Composition: Mainly consists of roller wheels, bearing supports for rollers, clamping and adjustment devices, as well as drive mechanisms.How it works: The double-light roller crusher rotates from two circular rollers in the opposite direction, and the ore enters between the two rollers. Due to the action of friction, the ore is carried into the crushing space between the rollers and is squeezed and crushed. The crushed product is excreted from the gapbetween the two rolls under the action of its own weight. The minimum distance between the two rolls is the width of the discharge mouth, and the maximum particle size of the crushed product is determined thereby.

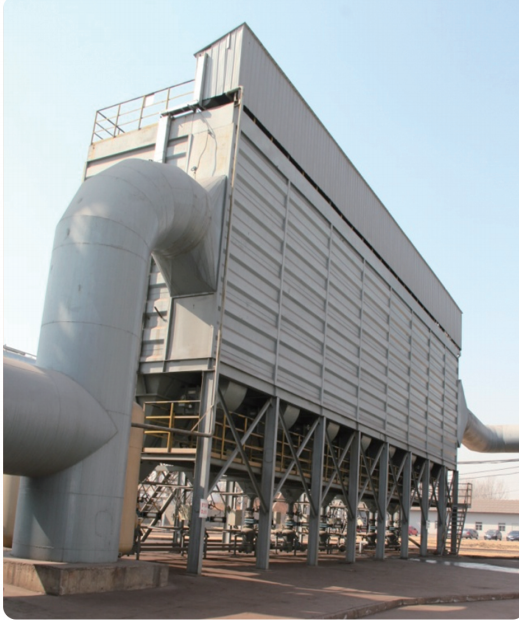

Equipment that separates dust from flue gas is called a dust collector or dust removal equipment. The performance ofa dust collector is expressed by the amount of gas that can be treated, the resistance loss when gas passes through the dust collector, and the dust removal efficiency.Divided into three categories based on their working principles:1) Filter-type dust collectors include baghouse dust collectors and particle layer dust collectors, etc.2) Electrostatic precipitator3) Magnetic dust collectorAccording to the dusting method, it is divided into:1) Dry dust collector2) Semi-dry dust collector3) In industrial applications, electrostatic bag composite dust collectors and bag-type dust collectors are more commonly used for wet dust removal systems.

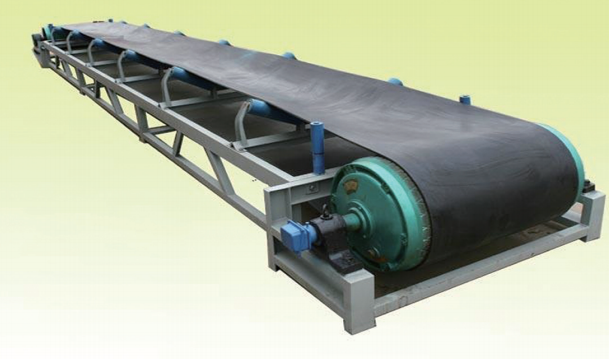

DT Belt ConveyorDT general fixed belt conveyer is a conveyer with large capacity, low operating cost and wide range of use. The machine is suitable for the conveyance of bulk or component materials, and can be carried in a single unit according to the requirements of the conveyancing process, or can be composed of multiple units or other conveyance (feeding) equipment to form a horizontal or inclined conveyance system. DJ Type Large Inclination Edge Belt ConveyorThe DJ type large-angle edge banding belt conveyor is mainly used for continuous transportation of loose materials with high angles, using wave-shaped edges and crossbars. The conveying angle is 0-90°.Features: With one device in a small space, horizontal tilt conveyance can be completed, having the advantages of high reliability of horizontal or small tilt conveying compared to general-purpose belt conveyors, energy saving, and the reliability and economy of lifting materials of the bulldozer conveyor.

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.