Description:

A hot blast furnace is a heat energy conversion device that uses fuel (blast furnace gas, coke oven gas, converter gas, mixed gas, producer gas, calcium carbide furnace gas, natural gas, liquefied petroleum gas, diesel, heavy oil, pulverized coal, and garbage, etc.) to burn in the furnace to release chemical energy, heating low-temperature air to a certain temperature. Hot blast furnaces can also use other thermal energy (such as electricity and waste heat) to heat the air.

Key Features:

1. Compatible with a wide range of fuels, it can be used to manufacture hot air furnaces fueled by blast furnace gas, coke oven gas, converter gas, mixed gas, producer gas, natural gas, liquefied petroleum gas, chemical waste gas, heavy oil, diesel, and pulverized coal.

2. Output hot air temperature is controlled within a ±5°C temperature differential.

3. Automatically adjusts fuel and air supply based on the control point temperature, making it easy to use.

4. Non-standard design offers high specificity and meets user requirements.

5. Wide output hot air temperature control range meets the drying needs of various industries.

6. Continuously provides purified hot air at a constant temperature and pressure.

7. Fully automatic operation, utilizing imported electrical components, ensures high reliability and accuracy, and is compatible with industrial network control.

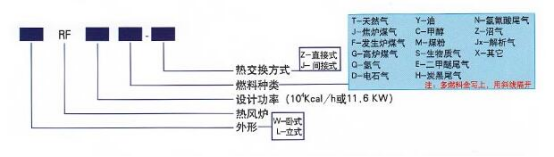

Model description meaning:

Technical performance table:

Model

| Heating capacity | Design gas volume | Gas volume | Power adjustment range | Thermal efficiency |

WRF50T-Z | 50X10⁴ | 60 | 20-70 | 200-700 | >95 |

WRF100T-Z | 100X10⁴ | 120 | 40-140 | 400-1300 | >95 |

WRF200T-Z | 200X10⁴ | 240 | 60-300 | 700-2600 | >95 |

WRF300T-Z | 300X10⁴ | 360 | 100-400 | 1100-4000 | >95 |

WRF400T-Z | 400X10⁴ | 480 | 150-550 | 1400-5200 | >95 |

WRF500T-Z | 500X10⁴ | 600 | 200-650 | 1800-6500 | >95 |

WRF600T-Z | 600X10⁴ | 720 | 250-800 | 2000-8000 | >95 |

WRF800T-Z | 800X10⁴ | 960 | 300-1100 | 2800-10000 | >95 |

WRF1000T-Z | 1000X10⁴ | 1200 | 400-1400 | 3500-13000 | >95 |

WRF1200T-Z | 1200X10⁴ | 1440 | 450-1600 | 4200-16000 | >95 |

WRF1500T-Z | 1500X10⁴ | 1800 | 500-2000 | 5500-20000 | >95 |

WRF2000T-Z | 2000X10⁴ | 2400 | 750-2700 | 7000-25000 | >95 |

WRF2500T-Z | 2500X10⁴ | 3000 | 900-3300 | 9000-32000 | >95 |

WRF3000T-Z | 3000X10⁴ | 3600 | 1100-4000 | 11000-40000 | >95 |

WRF3500T-Z | 3500X10⁴ | 4200 | 1300-4800 | 13000-45000 | >95 |

WRF4000T-Z | 4000X10⁴ | 4800 | 1500-5500 | 14000-50000 | >95 |

WRF4500T-Z | 4500X10⁴ | 5400 | 1700-6000 | 16000-60000 | >95 |

WRF5000T-Z | 5000X10⁴ | 6000 | 1800-6600 | 1 8000-65000 | >95 |

Note:①Qdw=8500Kcal/Nm³ Natural gas, horizontal direct-fired hot air furnace as an example ②Product specifications can also be designed according to user requirements | |||||

Keywords

Download

2025-09-02

13.4KB

Hot Air Furnace

Contact Us

Classification:

Case Introduction

Anhui Weida coke oven gas hot blast stove application site

Beijing Bank of China Tianye Natural Gas Flue Gas Heating Hot Air Furnace Application Site

Workshop produces hot air furnace finished products

Application site of flue gas heating hot blast furnace in Dadonghai, Fujian

Application site of blast furnace gas hot blast furnace in Fujian Longjing Zhongyang Iron and Steel Project

Blast furnace gas and flue gas heating hot blast furnace application site in Tianjin

Harbin natural gas hot air furnace drying dry mix mortar application site

Application site of natural gas hot air furnace for Henan Liming Heavy Industry's supporting mill

Jiangsu Haiqi's natural gas hot air furnace application site in the overseas calcium chloride industry

Jiangsu Haiqi calcium chloride industry natural gas hot air furnace application site

Jiangxi Ganfeng Lithium Industry has an annual production capacity of 10,000 tons of lithium salt supporting the acidification kiln hot blast furnace application site, with a total of 6 sets in 3 phases

Qingdao Doublestar waste tire pyrolysis, granulation and comprehensive utilization heating and drying system

Shougang Jingtang Catalyst Analysis Coke Oven Gas Hot Blast Furnace Application Site

Tangshan Six Silicon 60×104kcalh Natural Gas Hot Air Furnace Application Site

Yunnan Tin Industry Producer Gas Hot Air Furnace Application Site

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.