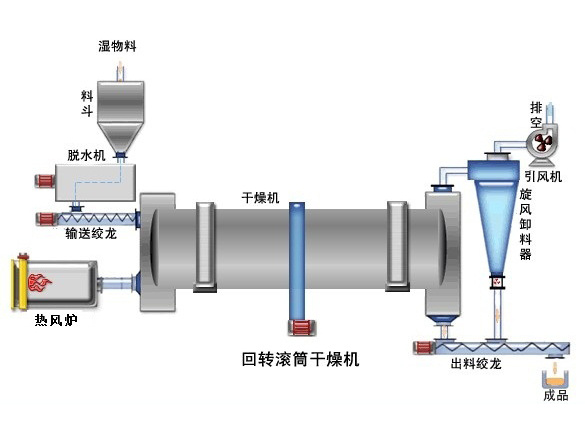

System Components:

It is mainly composed of a rotating body, a lifting plate, a transmission device, a supporting device and a sealing ring.

How it works:

A rotary dryer is a cylindrical drum slightly tilted from the horizontal. Material is fed into the drum from the higher end. Depending on the drying characteristics of the material, the high-temperature flue gas can flow into the drum either concurrently or countercurrently. Numerous lifting plates are installed on the inner wall of the drum. As the drum rotates, the material is continuously lifted and evenly distributed, allowing it to come into contact with the high-temperature flue gas. Moisture content absorbs heat, transforming into steam, which is then discharged through the dust removal system along with the flue gas. Under the influence of gravity, the material gradually flows to the drum outlet and is discharged.

Product performance features:

1. Wide Application: Widely used in mining, mineral concentrate, tailings, coal, metallurgy, chemical industry, light industry, building materials, and food industries. Suitable for a variety of materials, including powders, granules, and materials with high viscosity and humidity. Our company can customize and design drying solutions for different materials.

2. High Heat Exchange Efficiency: To reduce energy consumption and heat loss, our rotary dryers utilize integrated insulation materials to improve thermal efficiency and minimize heat loss. The internal material handling system and area within the drum are strategically configured according to the material's properties, extending the material's residence time within the dryer, improving thermal efficiency, and minimizing high-temperature gas loss.

3. High Usability: Each unit utilizes an automatic control system that allows for continuous adjustment of feed and discharge speeds, heat and temperature supply, main unit speed, and dehumidification fan, tailored to the material's properties, ensuring optimal operating conditions.

Technical performance table:

model( mm ) | inclination( % ) | Speed( r/min ) | Intake air temperature(℃) | power( kw ) |

production capacity( t/h ) | weight( t ) |

JSHZΦ600x6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

JSHZΦ800x8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

JSHZΦ800x10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

JSHZΦ1000x10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

JSHZΦ1200x10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

JSHZΦ1200x12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

JSHZΦ1500x12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

JSHZΦ1800x12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

JSHZΦ2200x12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

JSHZΦ2200x18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

JSHZΦ2200x20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

JSHZΦ2400x20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

JSHZΦ3000x20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

JSHZΦ3000x25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |

Keywords

Download

2025-09-02

12.3KB

Rotary Dryer

Contact Us

Classification:

Case Introduction

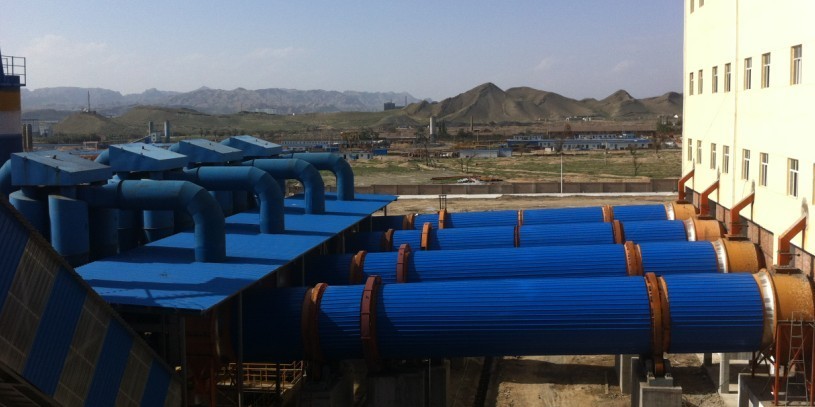

Rotary single-drum dryer

Qingdao Doublestar Waste Tire Pyrolysis, Granulation, Comprehensive Utilization, Heating and Drying Project - Rotary Dryer Application Site

Wuhai lignite drying application site

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.