Hydrogen is a flammable and explosive gas with an explosive concentration range of 4-75%, a wide range. Even low concentrations can cause explosions, making hydrogen combustion a significant challenge. Based on years of burner research and analysis of hydrogen's characteristics, our company has successfully developed a hydrogen burner and control system that ensures proper hydrogen combustion, utilizes waste gas, reduces pollution, and saves costs. This system is now widely used in the chemical industry, as well as in research at design institutes and research centers.

Performance characteristics:

1. Primarily used in the chlor-alkali industry and laboratories, where hydrogen is a byproduct of the production process.

2. Due to the rapid combustion and explosive nature of hydrogen, the hydrogen burner utilizes a diffuse external-mix combustion method. The burner nozzle divides the gas into two zones: the gas-rich zone in the center of the flame and the air-rich zone at the edge of the flame.

3. Before venting the hydrogen pipeline, nitrogen is purged to displace the air in the pipeline and prevent hydrogen and air from mixing.

4. Before hydrogen ignition, in addition to purging the furnace, nitrogen is also purged into the pipeline and burner interior. After successful ignition, the nitrogen is gradually replaced with natural gas, and the nitrogen is gradually withdrawn.

5. A nitrogen purge is also designed to prevent flashback after accidental burner flameout and normal shutdown.

6. A protective control system is included, enabling programmed ignition, automatic control, and fault protection.

7. Separate gas and air damper channel control is implemented, with the air/gas ratio K value set online to accurately control the air/gas ratio and prevent errors caused by connecting rod transmission. 8. Compatible with boilers, hot air furnaces, various incinerators, etc.

9. Custom designs can be made based on the user's site conditions.

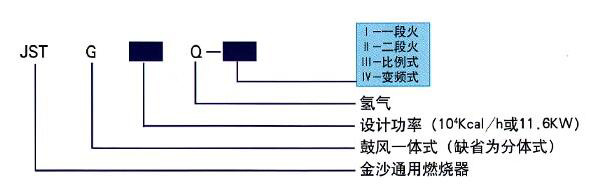

The meaning of the model expression:

Technical performance table:

| Model | Design Power (kW) | Design Gas Pressure (kPa) | Design Gas Consumption (Nm³/h) | Power Adjustment Range (kW) | Gas Consumption Range (Nm³/h) | Fan Power (kW) |

| JST150 | 200 | 5 | 60 | 60~250 | 20~80 | 0.75 |

| JST300 | 350 | 5 | 120 | 120~500 | 50~200 | 1.5 |

| JST600 | 700 | 5 | 240 | 250~1000 | 100~350 | 2.2 |

| JST1500 | 1700 | 5 | 800 | 500~2000 | 200~700 | 3 |

| JST2000 | 2300 | 5 | 800 | 600~3500 | 250~1500 | 4 |

| JST3000 | 3000 | 5 | 1200 | 1000~4000 | 400~2000 | 7.5 |

| JST4000 | 4200 | 5 | 1600 | 1200~5500 | 500~2500 | 18.5 |

| JST6000 | 7000 | 5 | 2400 | 2000~8500 | 700~3000 | 22 |

| JST12000 | 14000 | 5 | 4800 | 4500~17000 | 1600~6000 | 55 |

| JST15000 | 17400 | 5 | 6000 | 6000~21500 | 2000~7500 | 55/75 |

| JST24000 | 28000 | 5 | 9600 | 9000~34000 | 3200~12000 | 75/110 |

| JST30000 | 34800 | 5 | 12000 | 12000~43000 | 4000~15000 | 75/110 |

Note:

① Using hydrogen gas with Qdw=2500Kcal/Nm3as an example

② Product specifications can be custom-designed according to user requirements

Keywords

Download

Hydrogen Burner

Contact Us

Classification:

Case Introduction

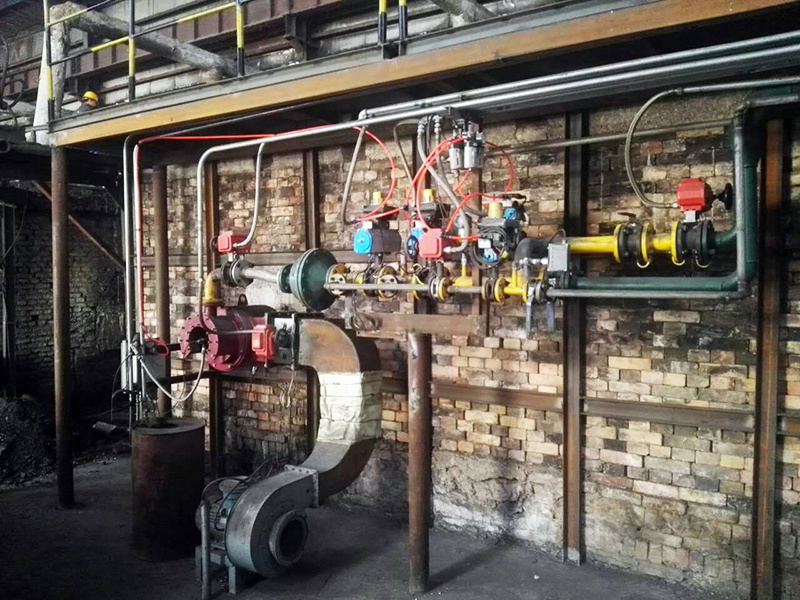

Binhai Petrochemical hydrogen burner application site, supporting 10 ton steam boiler calcium carbide furnace exhaust gas burner application site, supporting boiling furnace

The hydrogen burner of East China University of Science and Technology should be used on-site and experimentally

Inner Mongolia Ruida Taifeng hydrogen burner application site, supporting alkali stove

Qingdao Haijing Chemical hydrogen burner application site, supporting hot blast stove

Shandong Dadi hydrogen burner application site, supporting hot blast stove

Shandong Yantai hydrogen burner application site, supporting hot blast stove

Shouguang Wanrui Chemical hydrogen burner application site, supporting thermal oil furnace

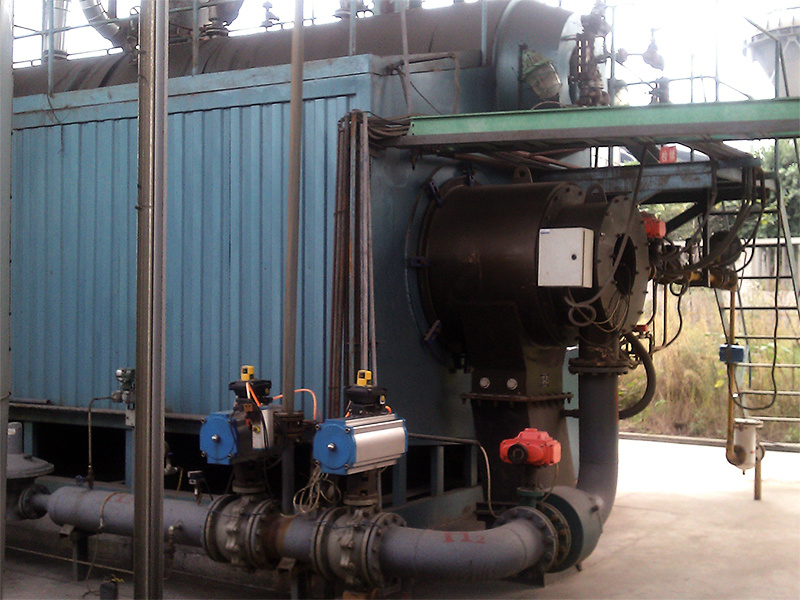

Sichuan Yingtianhui Chemical hydrogen burner application site, equipped with a 10-ton steam boiler

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.