The pulverized coal burner produced by our company is improved based on the working principle of the swirl-type pulverized coal burner specially designed by the U.S. Department of Energy and the actual technical requirements of industrial furnaces (industrial boilers). It has low manufacturing cost and is easy to use. It is suitable for oil-free and gas-free fuel processes and projects that use coal instead of oil or gas for combustion while ensuring clean and environmental protection.

Performance characteristics:

1. The pulverized coal burner features uniform fuel distribution and optimal air flow at the outlet. The mixing point of the secondary and primary air is optimal, ensuring timely ignition and intense combustion.

2. A well-organized aerodynamic field is achieved, with dedicated mechanisms adjusting the primary and secondary air to the mixing point. While the primary air generally exhibits weak rotation, the secondary air, through a dedicated mechanism, generates strong rotation. Depending on the coal type and operating conditions, a portion of the secondary air is adjusted from a circular swirl to a circular straight flow, thereby adjusting the flame shape. Therefore, this product utilizes a diffusion-type combustion method and offers excellent adjustability, allowing for different adjustment methods for different coal types.

3. A dedicated ignition and stabilization combustion channel is provided to modify the flame shape and assist the burner in quickly establishing a main flame that can independently and stably burn.

4. The purpose of the diffusion cone is to adjust the flame spread angle at the burner outlet, also known as a flame stabilizer. The flame spread should be adjusted according to the coal quality to achieve a balanced flame fullness.

5. Pulverized coal burners can also be designed as dual-purpose burners for both natural gas and pulverized coal.

System composition:

The pulverized coal combustion system consists of a silo, a pulverized coal metering and conveying system, pulverized coal burners, a combustion-supporting fan, and a control system. Pulverized coal falls from the silo through a drop pipe, passes through an electric arc valve, and enters a screw feeder. The screw feeder then feeds the pulverized coal into a plate flowmeter, where the plate flowmeter measures the flow rate and adjusts the screw feeder speed based on the actual flow rate to ensure proper feeding. After being measured by the flowmeter, the pulverized coal enters the feed box of the pneumatic screw conveying pump and is propelled forward by the feeder. The pulverized coal enters the mixing chamber, where it is vaporized by the air at the fan outlet. This air is then fed into a conveying pipeline, mixed with the pulverized coal burner, and burned in the furnace.

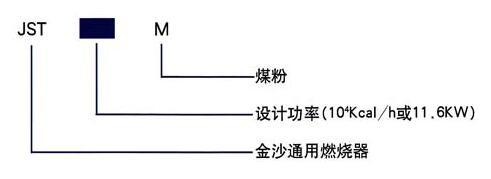

The meaning of the model expression:

Technical performance table:

| Model | Design Power (kW) | Normal Combustion Rate (t/h) | Maximum Rate (t/h) | Thermal Efficiency (%) |

| JST50M | 600 | 0.03-0.1 | 0.12 | >95 |

| JST100M | 1200 | 0.06-0.2 | 0.25 | >95 |

| JST200M | 2300 | 0.12-0.4 | 0.5 | >95 |

| JST300M | 3500 | 0.18-0.6 | 0.75 | >95 |

| JST400M | 4700 | 0.24-0.8 | 1.0 | >95 |

| JST500M | 5800 | 0.3-1.0 | 1.2 | >95 |

| JST600M | 7000 | 0.36-1.2 | 1.5 | >95 |

| JST800M | 9300 | 0.48-1.6 | 2.0 | >95 |

| JST1000M | 11600 | 0.6-2.0 | 2.5 | >95 |

| JST1200M | 14000 | 0.72-2.4 | 3.0 | >95 |

| JST1500M | 17400 | 0.9-3.0 | 3.5 | >95 |

| JST2000M | 23200 | 1.2-4.0 | 4.5 | >95 |

| JST2500M | 29000 | 1.5-5.0 | 5.5 | >95 |

| JST3000M | 34800 | 1.8-6.0 | 6.5 | >95 |

| JST3500M | 40000 | 2.1-7.0 | 7.5 | >95 |

| JST4000M | 46000 | 2.4-8.0 | 8.5 | >95 |

| JST4500M | 52000 | 2.7-9.0 | 9.5 | >95 |

| JST5000M | 58000 | 3.0-10.0 | 10.5 | >95 |

Note:

① Using pulverized coal with Qdw=5000Kcal/kg as an example

② Product specifications can be custom-designed according to user requirements

Keywords

Download

Pulverized Coal Burner

Contact Us

Classification:

Case Introduction

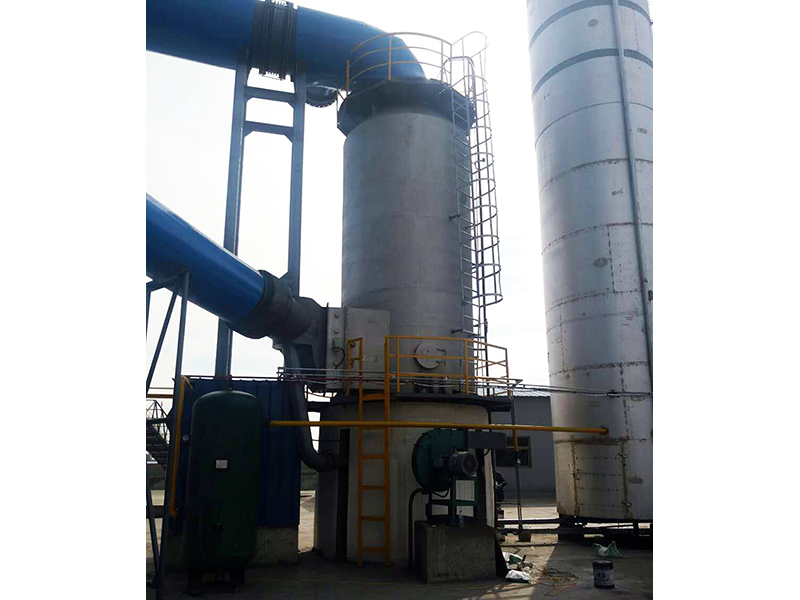

Application Site of Vertical Pulverized Coal Hot-Air Furnace

Pulverized Coal Hot-Air Furnace

Korean Wood Powder Hot-Air Furnace

Pulverized Coal Hot-Air Furnace

The application site of Gaolan pulverized coal burner in Gansu Province is equipped with a 20-ton hot water heating boiler

Gansu Tianzhu pulverized coal burner application site is equipped with a 10-ton hot water heating boiler

Henan Liming Heavy Industry Liangshan Project pulverized coal hot blast stove application site

Shandong Linyi Hongyuan thermal pulverized coal burner application site, supporting steam boiler

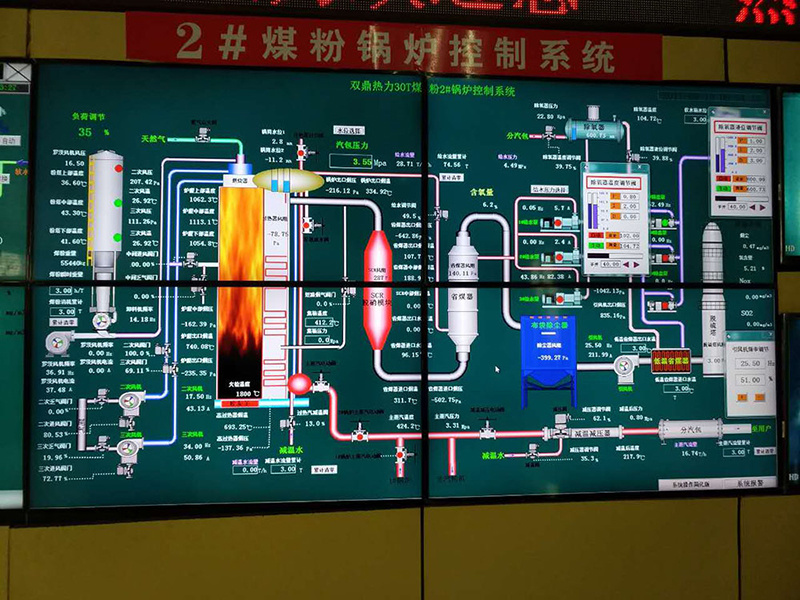

Shandong Shuangding thermal pulverized coal burner application site is equipped with a 40-ton steam boiler

Shandong Yuehua Energy pulverized coal burner application site

Tangshan Ruifeng Iron and Steel vertical pulverized coal hot blast furnace installation site

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.