How it works:

A vertical dryer uses a fan to draw hot air from a hot air furnace (or exhaust from various heat sources) directly into the dryer's circulating air duct. The formed material is transported to the furnace roof by a belt conveyor or elevator, where it is evenly distributed across the entire roof by a distribution device. The material slowly descends on its track by gravity while exchanging heat with the strong air. Evaporated moisture is then randomly carried away by the strong air. After approximately two hours of evaporation, the material is dried.

Product performance characteristics:

1. High Thermal Efficiency: The furnace consists of three sections: a preheating section, a heating section, and a cooling section. Low-temperature hot air dries the pellets directly in the heating section, and the residual heat is used to preheat the upper section of the furnace, which improves thermal energy consumption and saves 20-30% energy when drying the same amount of material.

2. Easy to Use and Simple Maintenance: The furnace has no moving parts, requiring no routine maintenance. This is unmatched by traditional drying equipment.

3. Quantified Discharge: The vibration motor's on-time is proportional to the discharge volume, allowing the amount to be adjusted simply by controlling the vibration motor's on-time.

4. Simultaneous Screening and Discharge: A screening device is installed at the discharge point of the vertical drying bin. The dried pellets and some powder are screened during the discharge process, separating the pellets from the powder. This eliminates the need for separate screening equipment, resulting in cost savings and a compact design.

5. Excellent Dust Removal: Dust removal ducts are pre-installed at both the upper loading and lower discharge points of the drying bin. When connected to on-site dust removal equipment, these ducts effectively prevent smoke and dust from escaping. 6. Economical Features: Compared with currently common flip-plate drying ovens, the investment cost is reduced by half; the floor space required is reduced by 1/5-1/3; and energy consumption and operating costs are significantly reduced.

7. Usage Features: This product has excellent process compatibility and is easily connected to other equipment in the production line and automated, allowing for continuous operation, high efficiency, and high output.

Technical performance table:

| Model | Initial Moisture | Final Moisture | Output(t/h) | Standard Coal Consumption(kg/t) | Power Consumption(kw/t) | Weight(t) | ||

| Clay | Slag | Coal | ||||||

| JSHL-2014 | 25% | 2% | 6~7.8 | 10~12.6 | 8~10 | 20~25 | 2~3 | 17 |

| JSHL-2014 | 25% | 2% | 7~8.6 | 12~14 | 9~12 | 18~23 | 1.8~2.6 | 19 |

| JSHL-2016 | 25% | 2% | 8~11 | 13~16 | 10~14 | 17~22 | 1.6~2.2 | 21 |

| JSHL-2216 | 25% | 2% | 9~12 | 15~17 | 12~15 | 16~20 | 1.5~2.1 | 26 |

| JSHL-2218 | 25% | 2% | 10~13 | 16~18 | 14~16 | 14~18 | 1.5~2.0 | 28 |

| JSHL-2220 | 25% | 2% | 11~13.8 | 17~20 | 15~17 | 13~16 | 1.4~1.8 | 30 |

| JSHL-2222 | 25% | 2% | 13~15 | 19~23 | 16~19 | 13~14 | 1.4~1.6 | 32 |

| JSHL-2516 | 25% | 2% | 17~22 | 22~28 | 18~26 | 13~16 | 1.4~1.8 | 38 |

| JSHL-3018 | 25% | 2% | 22~27 | 34~45 | 23~32 | 14~18 | 1.5~2.0 | 45 |

| JSHL-3210 | 25% | 2% | 25~32 | 38~52 | 26~39 | 17~20 | 1.8~2.3 | 48 |

Keywords

Download

2025-09-02

12.3KB

Vertical Dryer

Contact Us

Classification:

Case Introduction

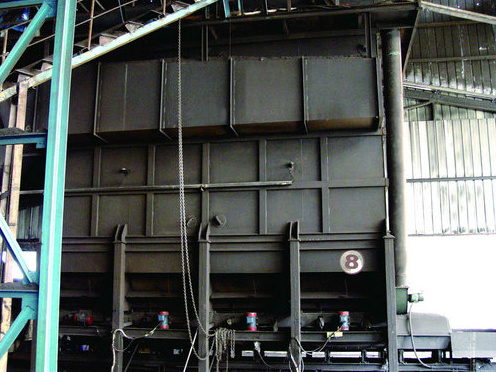

Jilin Shouxin Weiye powder bonding ball project vertical dryer application site

Vertical dryer application site

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.