As environmental policies impose stricter requirements on nitrogen oxide emissions and desulfurization treatment in industrial waste gas, flue gas purification (desulfurization, denitrification, and dust removal) has become an environmental protection task for all industrial enterprises. Desulfurization and denitrification catalysts have certain flue gas temperature requirements. However, industrial exhaust gases (such as steel mill sintering flue gas, coke oven flue gas, and industrial kiln exhaust gas) do not reach the required temperatures for desulfurization and denitrification, so a flue gas heating and hot air system is required to supplement the heat.

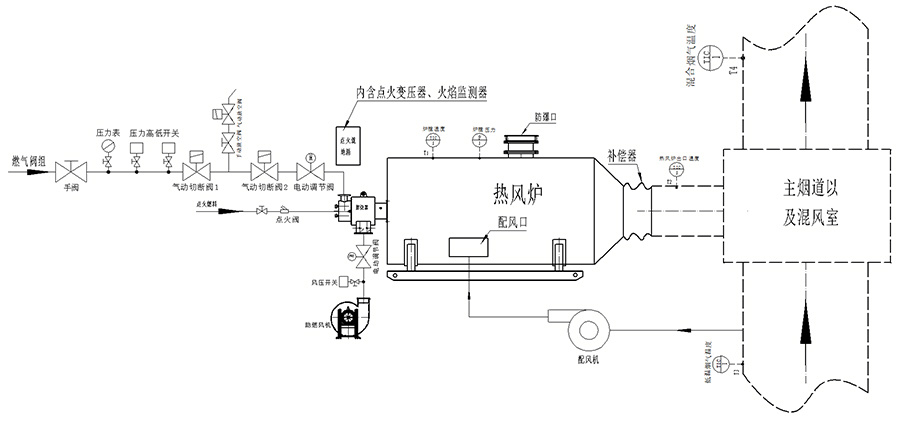

Process principle:

After combustion in the hot blast furnace's combustion chamber, the gas is mixed with supply air (either raw flue gas or air) in the furnace's mixing chamber, generating hot air at 600-1000°C (designed to suit user requirements). Under negative pressure at the furnace tail, hot air enters the user's main flue's air mixing chamber, where it mixes with a large amount of raw, low-temperature flue gas from the main flue to reach the required temperature for the user's subsequent desulfurization and denitrification equipment. After passing the treatment, it enters the desulfurization and denitrification equipment and is discharged into the environment through the chimney. This hot air system can also be used to supplement flue gas heat for desulfurization and denitrification catalyst desorption.

(Note: Depending on the fuel type and on-site process layout, a direct-fired burner with a combustion channel installed directly in the main flue can also be used for flue gas supplemental heating.)

Supplemental heating fuels can be selected based on site conditions and include combustible gases such as blast furnace gas, coke oven gas, natural gas, calcium carbide exhaust gas, and producer gas, as well as liquid fuels such as diesel.

Process schematic:

Compose:

The flue gas heating and heating hot air system primarily consists of a gas-fired hot air furnace, burner, combustion-supporting fan, circulating air distribution fan (optional based on process design), gas process valve train and piping, ignition piping, measuring instruments, and other equipment and components, as well as an automatic control system. The system automatically adjusts the gas and combustion-supporting air volumes based on the mixed flue gas temperature (or the temperature inside the desulfurization and denitrification towers). The required heat can be adjusted at any time to meet the requirements of varying on-site operating conditions, even with changes in the heated flue gas volume and temperature.

Patent certificate:

Download

Flue Gas Desulfurization and Denitrification Heating System

Contact Us

Classification:

Case Introduction

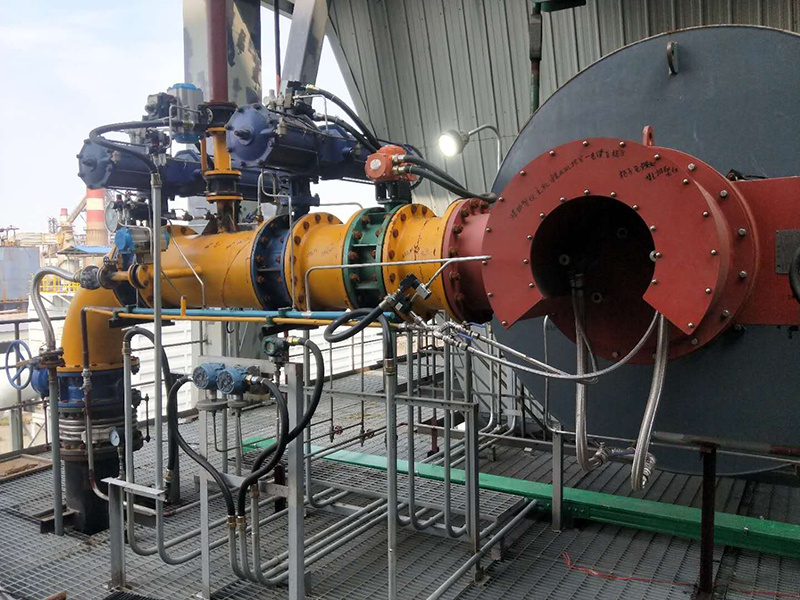

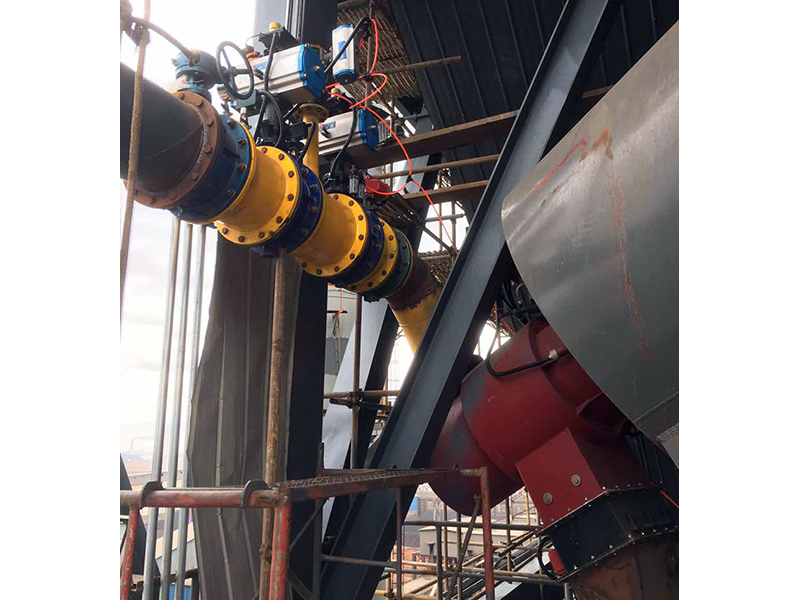

Anhui Weida Hongxing Iron and Steel Project blast furnace gas hot blast furnace application site

Beijing Asia-Pacific Qian'an Sinochemical Project Coke oven gas hot blast stove application site

Beijing Bank of China Tianye natural gas flue gas heating hot blast stove application site

Fujian Longjing Zhongyang Iron and Steel Project blast furnace gas vertical hot blast furnace application site

Blast furnace gas flue gas heating hot blast furnace Tianjin application site

Jiangsu Kehang Donghua Iron and Steel Project blast furnace gas direct combustion application site

Jiangsu Langrun Shandong Longsheng Iron and Steel Project blast furnace gas hot blast furnace application site

The application site of direct combustion of blast furnace gas in Lianxin Iron and Steel Project

The application site of direct combustion of blast furnace gas in Shagang project

Sichuan Hanshen Chaohu Project natural gas direct combustion application site

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.