Coke oven gas is a by-product of the coking industry. After purification, it is also called city gas. It has been widely used in coking, steel, chemical and coking-related industries. Due to its extremely high hydrogen content and rapid combustion, coke oven gas is also more explosive and has combustion instability than other fuels. The coke oven gas burner developed by our company takes fuel properties into consideration in its design, and has made special treatments for ignition, purge, regulation, and backfire prevention. On the basis of combustion, it adopts advanced control technologies such as PLC, touch screen, and industrial computer to ensure operational reliability.

Performance characteristics:

1. The ignition source is directly coke oven gas, making it easy to use.

2. Designed specifically for the characteristics of coke oven gas, the system takes into account the impact of tar on combustion and offers an optional heating filter.

3. Different treatments are implemented on-site for different customers, depending on the flammability and explosiveness of the fuel.

4. There are no special requirements for gas pressure or composition; the user can specify the values before ordering. The typical design gas pressure is 5-8 kPa.

5. The flame size can be customized based on the customer's furnace size and requirements.

6. Control systems can be configured to meet customer requirements, including staged fire, proportional damper adjustment, proportional frequency conversion, touch screen digital control, and industrial computer variable frequency control.

7. Separate gas and damper channel control is implemented, and the air/gas ratio K value is set online for precise control of the air/gas ratio, preventing errors caused by connecting rod transmission.

8. The system features various interlock protections, including flame overtemperature, overpressure, and valve block leak detection.

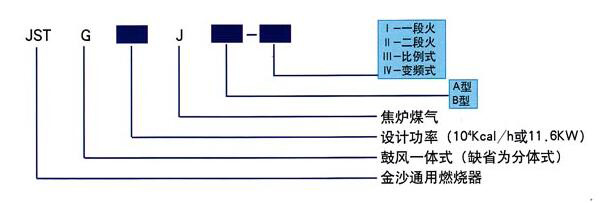

The meaning of the model expression:

Technical performance table:

| Model | Design Power (kW) | Design Pressure (kPa) | Design Gas Consumption (Nm³/h) | Power Adjustment Range (kW) | Fan Power (kW) |

| JST30J | 350 | 5 | 75 | 150~400 | 0.75 |

| JST60J | 700 | 5 | 150 | 300~750 | 1.5 |

| JST100J | 1200 | 5 | 250 | 500~1300 | 2.2 |

| JST120J | 1400 | 5 | 300 | 600~1500 | 3 |

| JST150J | 1700 | 5 | 400 | 700~2000 | 5.5 |

| JST200J | 2300 | 5 | 500 | 1000~2500 | 7.5 |

| JST300J | 3500 | 5 | 750 | 1500~4000 | 15 |

| JST400J | 4600 | 5 | 1000 | 2000~5000 | 18.5 |

| JST500J | 5800 | 5 | 1300 | 2500~6200 | 22 |

| JST600J | 7000 | 5 | 1500 | 3000~7500 | 30 |

| JST1200J | 14000 | 5 | 3000 | 6000~15000 | 55 |

| JST2400J | 28000 | 5 | 6000 | 12000~32000 | 75/110 |

| JST3000J | 34800 | 5 | 7200 | 15000~40000 | 75/110 |

Note:

① Using coke oven gas with Qdw=4200Kcal/Nm3 as an example

② Product specifications can be custom-designed according to user requirements

Keywords

Download

Coke Oven Gas Burner

Contact Us

Classification:

Case Introduction

Anhui Weida split coke oven gas burner application site, supporting flue gas heating system

Jingtang Port Hengtong split coke oven gas burner application site, supporting 10 tons WNS boiler

Jingtang Port Hengtong split coke oven gas double-mouth burner application site, equipped with 20-ton WNS boiler

Inner Mongolia mechatronic coke oven gas burner application site, equipped with 10 ton steam boiler

Shanxi Jiexiu multi-channel coke oven gas burner application site

Shanxi Jinyu 35 million kcal h split coke oven gas burner application site, supporting rotary kiln

Shougang Jingtang mechatronic coke oven gas burner application site, supporting denitrification analysis system

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.