The blast series burners can be divided into two types according to their structure: mechatronic and split types. This series of burners consists of multiple internal mixing burners, external mixing burners and air distribution ducts. To facilitate combustion adjustment, air enters the burner in two parts during combustion, namely primary air and secondary air. The flame shape and combustion conditions are adjusted by adjusting the air volume and wind speed of the primary and secondary air, making the combustion stable. It is suitable for high, medium and low pressure gases.

Performance characteristics:

1. This series of burners features a compact structure, attractive appearance, and easy installation.

2. It utilizes a combination of multi-head internal mixing and air dispersion for more stable combustion.

3. The typical natural gas design pressure is 8-10 kPa, but can be customized to meet the user's specific operating conditions.

4. The power adjustment range is wide: 30-110%.

5. The flame size can be customized to meet user requirements.

6. Various automatic control options are available: flame shutoff (damper flame shutoff control, variable frequency flame shutoff control), damper proportional control, variable frequency proportional control, touch screen digital control, industrial computer variable frequency proportional control, and more, to meet diverse user requirements.

7. Separate gas and damper channel control allows for online setting of the air/gas ratio K value, ensuring precise control of the air/gas ratio and preventing errors caused by connecting rod transmission.

8. The system features various interlock protections, including flame detection, overtemperature, overpressure, and valve block leak detection.

9. Manual combustion is also possible without the automatic control system, making adjustments extremely easy.

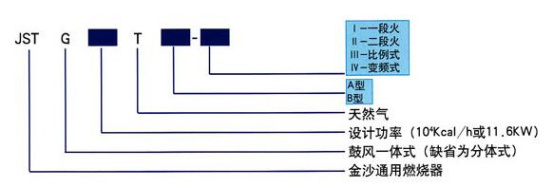

The meaning of the model expression:

Technical performance table:

| Model | Design Power(kW) | Design Gas Consumption(Nm³/h) | Gas Consumption Range(Nm³/h) | Power Adjustment Range(kW) | Flame Diameter(mm) | Flame Length(mm) | Motor Power(kW) | ||

| Long Flame | Short Flame | Long Flame | Short Flame | ||||||

| JST20T | 230 | 24 | 8~26 | 60~260 | 150 | 250 | 800 | 500 | 0.37 |

| JST30T | 350 | 36 | 12~40 | 100~390 | 200 | 350 | 900 | 600 | 0.37 |

| JST40T | 460 | 48 | 15~55 | 140~510 | 250 | 500 | 1000 | 700 | 0.37 |

| JST60T | 700 | 70 | 22~80 | 210~770 | 400 | 600 | 1200 | 800 | 0.75 |

| JST100T | 1200 | 120 | 36~130 | 420~1600 | 550 | 800 | 1400 | 1000 | 1.5 |

| JST150T | 1700 | 180 | 50~200 | 520~2000 | 600 | 900 | 2000 | 1200 | 2.2 |

| JST250T | 2900 | 300 | 90~350 | 950~3700 | 700 | 900 | 2600 | 1500 | 7.5 |

| JST300T | 3500 | 350 | 105~400 | 1100~4500 | 750 | 1000 | 3000 | 1800 | 11 |

| JST600T | 7000 | 700 | 210~800 | 2200~9000 | 850 | 1500 | 4000 | 2500 | 22 |

| JST1200T | 14000 | 1410 | 450~1600 | 4500~18000 | 1200 | 1800 | 6000 | 3500 | 37/55 |

| JST2400T | 28000 | 2820 | 900~3200 | 9000~35000 | - | - | - | - | 55/75 |

| JST3000T | 34800 | 3430 | 1000~4000 | 11200~43500 | - | - | - | - | 75/110 |

Note:

① Using natural gas with Qdw=8500Kcal/Nm3as an example

② Product specifications can also be custom-designed according to user requirements

Download

Blower-Type Natural Gas Burner Series

Contact Us

Classification:

Case Introduction

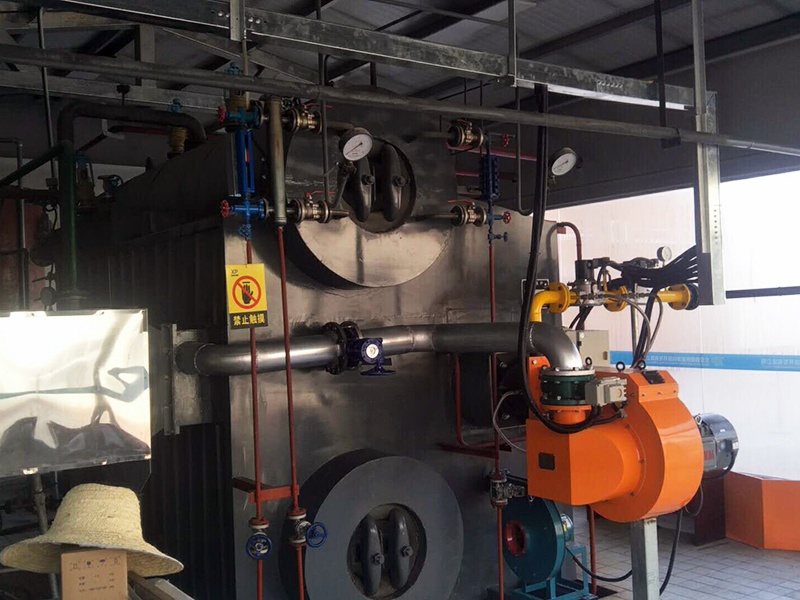

Beijing Xinpan mechatronics natural gas burner application site

Henan Liming Heavy Industry mechatronics natural gas burner application site

Henan Oilfield mechatronics natural gas burner application site

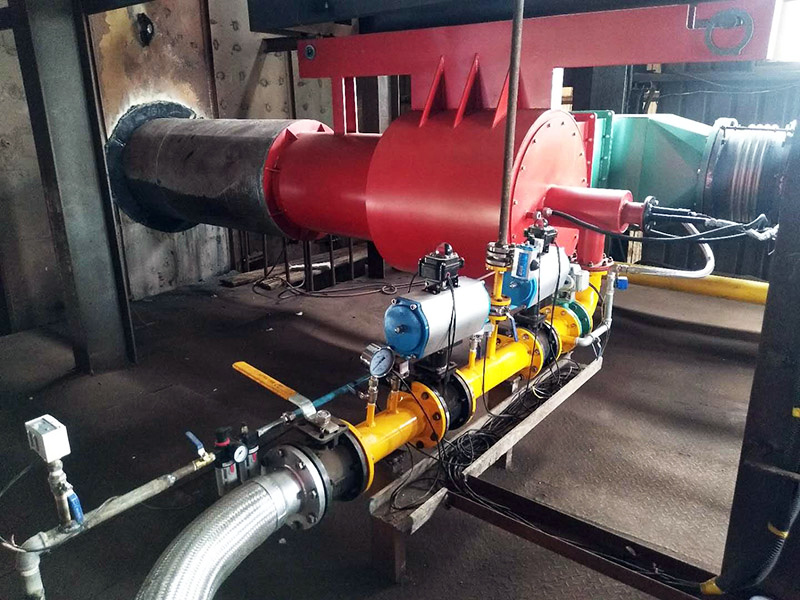

Hubei Yichang split natural gas burner application site

Jiangsu Shunda split natural gas burner supporting dryer application site

Lianyungang Jincheng split natural gas burner supporting rotary kiln application site

Qingdao Huatai split natural gas burner application site

Shaanxi split natural gas burner asphalt mixing plant application site

Sichuan Hanshen mechatronics integrated natural gas burner flue gas heating application site

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.