Scope of application:

The ignition furnace consists of three parts: a mechanical structure, a combustion system, and a control system. It is primarily used for sintering ignition in steel (iron) plants. It is suitable for a variety of gaseous and liquid fuels, such as blast furnace gas, coke oven gas, producer gas, mixed gas, and heavy oil. Fuel parameters can be specified by the user based on their fuel supply conditions, and different combustion devices can be designed to ensure baking performance.

Structural composition:

Ignition furnace: car-type steel structure, prefabricated refractory and insulation lining, furnace front piping and control valves; high swirl, strong mixing, low-power ignition burner.

Performance features:

1. Utilizing SJN-type high-swirl, high-mixing, low-power internal-mixing ignition burners, the system features short flames and excellent flame rigidity. Installed in two rows (large sintering machines use three rows, with one row preheating the charge surface), the system is densely arranged, creating a high-temperature, ribbon-shaped flame at the ignition port. This allows for uniform, direct ignition and impingement heating of the charge surface, facilitating rapid ignition of the added fuel and surface sintering.

2. The burner's heat-resistant parts are constructed of stainless steel, typically lasting over three years. The burner is installed as a single unit, making maintenance and replacement easy.

3. In conjunction with the short-flame burners, a low furnace chamber (400-500mm) and an enclosed furnace port are employed to minimize flame outflow and heat loss, thereby increasing ignition thermal intensity and reducing furnace weight.

4. Regarding the control of the air and gas flow in the ignition furnace, in addition to large valves at the air and gas inlets, each small burner is equipped with a regulating valve at the air and gas inlet to adjust heat supply and ignition uniformity during initial production and abnormal conditions.

Key Features:

1. Blast furnace gas: Calorific value 700Kcal/Nm³-850Kcal/Nm³; Design pressure >= 2KPa

2. Coke oven gas: Calorific value 4000Kcal/Nm³; Design pressure >= 1KPa

3. Producer gas: Calorific value 1100Kcal/Nm³; Design pressure >= 1KPa

4. Mixed gas: Calorific value 2000Kcal/Nm³-3000Kcal/Nm³; Design pressure >= 1KPa

5. Heavy oil: Calorific value 8000Kcal/Nm³-9000Kcal/Nm³; Design pressure >= 1.5-2.0KPa

名 称 | 单 位 | 烧 结 机 规 格(m2) | |||||||

18 | 24 | 36 | 52 | 60(64) | 90 | 130 | 180 | ||

台车宽度 | m | 1.5 | 1.5 | 1.5 | 2.0 | 2.0 | 3.0 | 3.0 | 3.5 |

台车速度 | m/min | (由用户提供) | |||||||

料层厚度 | mm | (由用户提供) | |||||||

烧结矿产量 | t/h | 36 | 48 | 72 | 100 | 110 | 162 | 200 | 260 |

燃料种类热值 | KJ/ N·m3 | 高炉煤气,Qe=800-750kcal/N·m3 | |||||||

煤气接口压力 | Kpa | ≥7.0 | |||||||

煤气含尘量 | mg/N·m3 | <10-20 | |||||||

点火煤气体量 | Nm3/h | 2200 | 2900 | 4300 | 6000 | 7000 | 9700 | 12000 | 16000 |

点火煤气体量 | Nm3/h | 1700 | 2300 | 3400 | 4800 | 5500 | 7500 | 9500 | 12500 |

点火时间 | sec | 60-90 | |||||||

点火温度 | ℃ | 1150±50℃ | |||||||

煤气预热温度 | ℃ | 200-300 | |||||||

空气预热温度 | ℃ | 300-400 | |||||||

点火炉膛高度 | mm/mm | 400-500 | |||||||

点火咀数量 | 个 | 12 | 12 | 12 | 23 | 24 | 36 | 36 | 36 |

点火嘴前空气压力 | kpa | 2.5-3.0 | |||||||

点火嘴前煤气压力 | kpa | 2.0-2.5 | |||||||

供风压力 | kpa | ≥7-8 | |||||||

双预热点火炉型号 |

| SDDL-1801.5 | SDDL-2401.5 | SDDL-36f1.5 | SDDL-52f2.0 | SDDL-60f2.0 | SDDL-90f3.0 | SDDL-130f3.0 | SDDL-180f3.5 |

Keywords

Download

Sintering Ignition Furnace

Contact Us

Classification:

Case Introduction

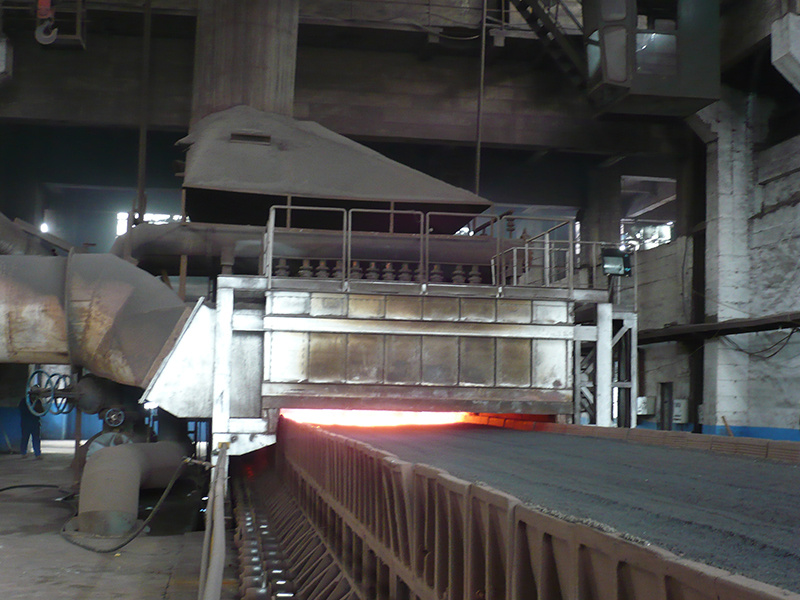

Belt sintering ignition furnace application site (1)

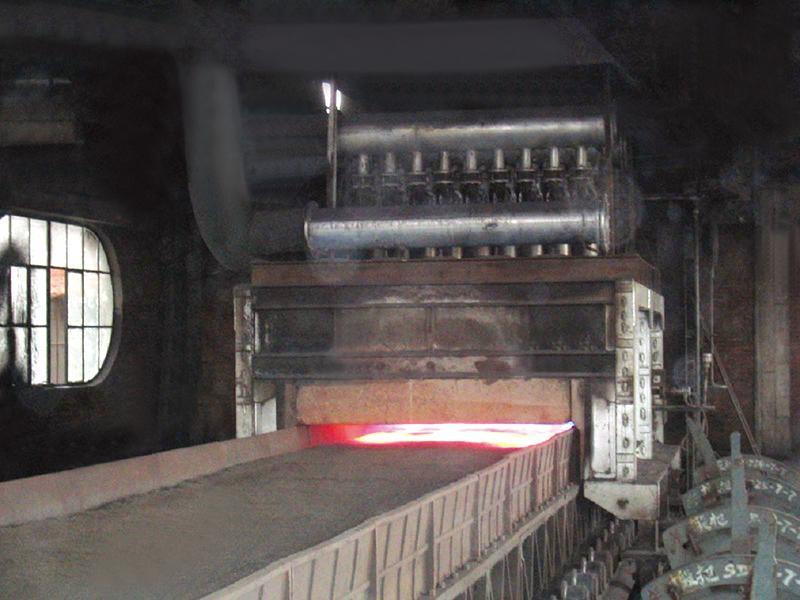

Belt sintering ignition furnace application site (2)

Belt sintering ignition furnace application site (3)

Ring type sintering ignition furnace application site

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.