Blast furnace gas burners are designed primarily for the combustion of blast furnace gas generated by steel companies. They are suitable for blast furnace gas of any pressure and calorific value. Utilizing multi-head internal mixing technology, these burners offer stable combustion and include automatic ignition, flameout protection, and automatic power adjustment. They require no firewood for heat storage and are easy to use. They are now widely used in steel companies and related enterprises.

Performance characteristics:

1. The calorific value of the fuel type is low, about 700-900Kcal/Nm³, and it is not easy to ignite.

2. There is no requirement for fuel pressure, and the given value can be designed and produced before ordering, usually the gas design pressure is 5-8KPa.

3. It is usually used on negative pressure combustion furnaces.

4. Control systems such as section fire type, damper adjustment proportional type, frequency conversion adjustment proportional type, touch screen digital control, and industrial computer frequency conversion proportional control can be configured according to user requirements.

5. Separate channel control of gas and damper, using online setting of wind/air ratio K value, accurately control the wind/air ratio to prevent errors caused by connecting rod transmission.

6. Equipped with flame extinguishing protection, automatic ignition, valve leak detection, over-temperature and over-pressure protection, status parameter display and other functions.

7. The control system follows the standard communication protocol and can communicate with the user's upper system.

8. Remove the automatic control system, manual combustion can be normal, and it is very easy to adjust.

The meaning of the model expression:

Technical performance table:

| Model | Design Power (kW) | Design Gas Consumption (Nm³/h) | Power Adjustment Range (kW) | Gas Consumption Range (Nm³/h) | Fan Power (kW) | Applicable Furnace Back Pressure (Pa) |

| JST15G | 200 | 200 | 60~250 | 70~270 | 0.75 | <1000 |

| JST30G | 350 | 400 | 120~500 | 120~550 | 1.5 | <1100 |

| JST60G | 700 | 800 | 250~1000 | 250~1100 | 2.2 | <1200 |

| JST150G | 1700 | 2000 | 500~2000 | 600~2300 | 3 | <1200 |

| JST200G | 2300 | 2500 | 600~3500 | 750~4000 | 4 | <1200 |

| JST300G | 3000 | 4000 | 1000~4000 | 1200~4500 | 7.5 | <1200 |

| JST400G | 4200 | 5000 | 1200~5500 | 1500~6500 | 18.5 | <1200 |

| JST600G | 7000 | 8000 | 2000~8500 | 2500~9000 | 20 | <1500 |

| JST1200G | 14000 | 16000 | 4500~17000 | 5000~18000 | 55 | <1500 |

| JST1500G | 17400 | 19000 | 6000~21500 | 6000~21500 | 55/75 | <2000 |

| JST2400G | 28000 | 30000 | 9000~34000 | 10000~36000 | 75/110 | <2000 |

| JST3000G | 34800 | 38000 | 12000~43000 | 12000~43000 | 75/110 | <2000 |

Note:

① Using blast furnace gas with Qdw=800Kcal/Nm3 as an example

② Product specifications can be custom-designed according to user requirements

Keywords

Download

Blast Furnace Gas Burner

Contact Us

Classification:

Case Introduction

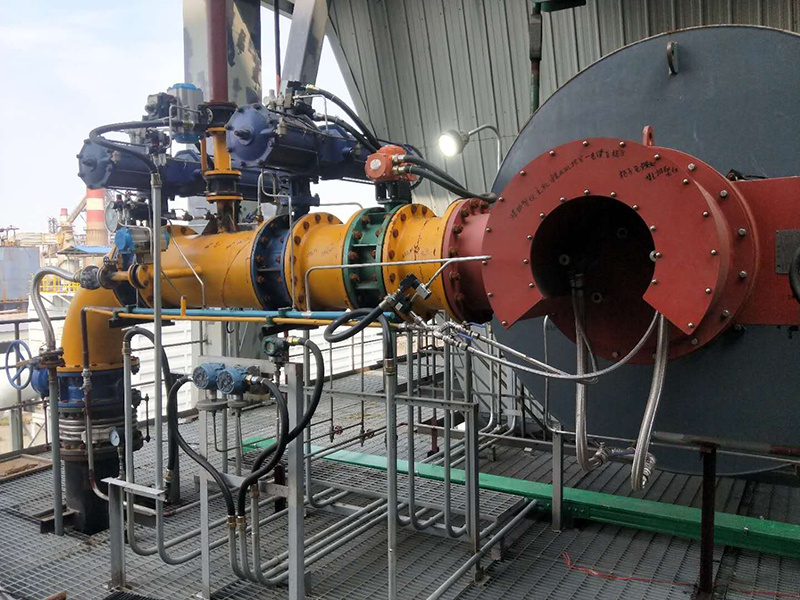

Anhui Weida Hongxing Iron and Steel Project blast furnace gas hot blast furnace application site

Jiangsu Kehang Donghua Iron and Steel Project blast furnace gas direct combustion application site

Jiangsu Langrun Shandong Longsheng Iron and Steel Project blast furnace gas hot blast furnace application site

2200×104kcal h blast furnace gas burner production site

Pancheng steel double-mouth blast furnace gas burner application site, equipped with a 15-ton steam boiler

Qian'an Rolling 18 blast furnace gas burners are applied to the application site, equipped with 35 tons of steam boilers

Shagang double-mouth blast furnace gas burner application site, supporting hot blast stove

Shandong Huayuan Rizhao blast furnace gas burner application site, equipped with a 20-ton steam boiler

Shanxi Jingang blast furnace gas burner application site, supporting hot blast stove

Contact Us

E-mail: yilin@cn-tsjsrs.com

Add: East side of Jingwu Road, Qian'an City, Hebei Province (within the modern equipment manufacturing industry cluster area)

Copyright © Tangshan Jinsha Combustion Heat Energy Co.,Ltd.