Description

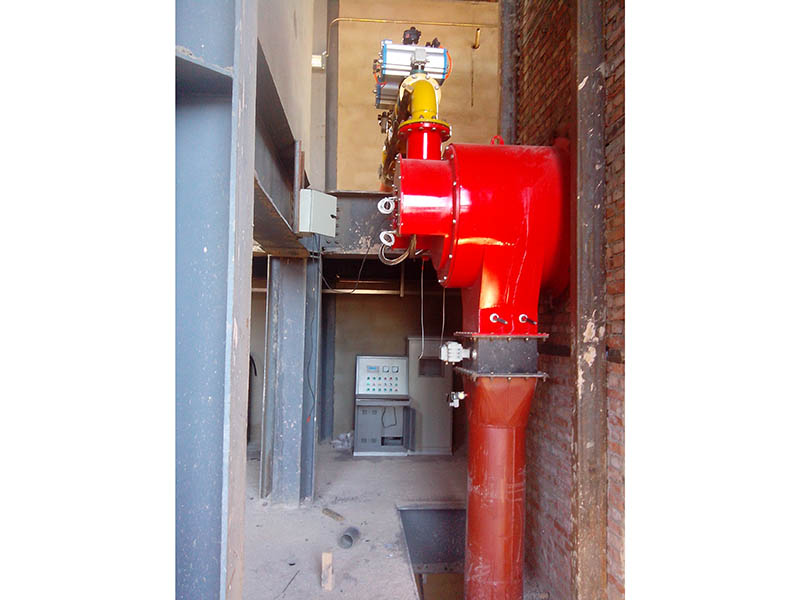

The blast furnace gas burner is mainly designed for burning the blast furnace gas generated from the iron and steel producion process. It is applicable for the blast furnace gas with any pressure and any calorific value. The burner adopts the multiple-head internal mixed technology, so the combustion is complete and stable and it can realize automatic ignition, fire-off protection, automatic fire adjustment and other functions. It is not required for heat accumulation when ignition and it has been widely applied in the iron and steel enterprise and the related enterprises.

Feature

1. The calorific value of the fuel is low, about 700-900Kcal/Nm3, it is not easy to ignite.

2. If there is no special requirements of the fuel gas pressure or components, the common designed pressure of the fuel gas shall be 5-8kpa. If the user send the required value to us, we will follow and preset the value into the system.

3. It is usually applied in the negative pressure combustion furnace.

4. The sectioned fire type, air door adjustment proportion type, frequency conversion regulation proportion type, touch screen digital control, frequency conversion regulation of the industrial personal computer and other control systems can be configured according to user's requirements.

5. The fuel gas and the air door shall be controlled by the separate channel, the air / gas proportion K value shall be set online to accurately control the air / gas proportion and prevent error caused by connecting rod transmission.

6. The system shall be equiped with flame detection, fire-off protection, automatic ignition, over-temperature/overpressure protection, leakage detection in valve groups and parameter display etc.

7. The control system shall be based on the standard communication protocol and can be connected with the upper system of the user for communication.

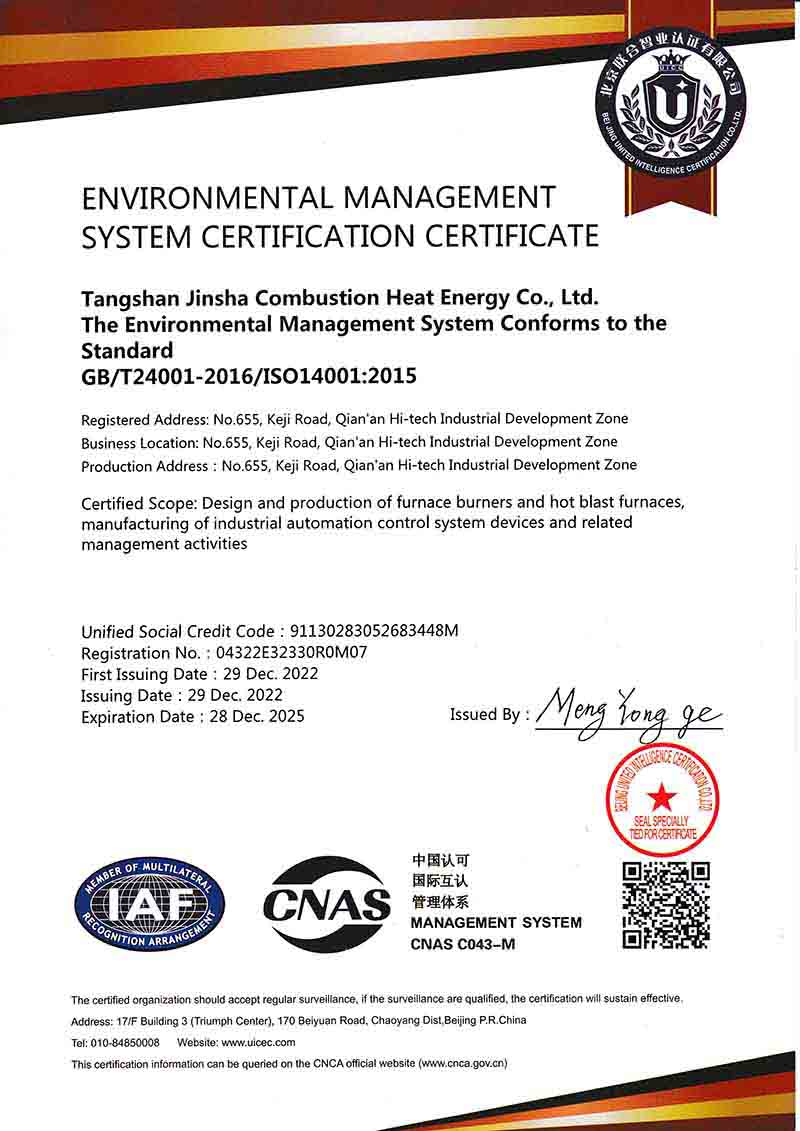

Certificates

EN

EN  CN

CN AR

AR BG

BG HR

HR CS

CS DA

DA FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO PT

PT RO

RO RU

RU ID

ID UK

UK VI

VI TH

TH TR

TR FA

FA MS

MS BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA KK

KK UZ

UZ AM

AM KY

KY