Description

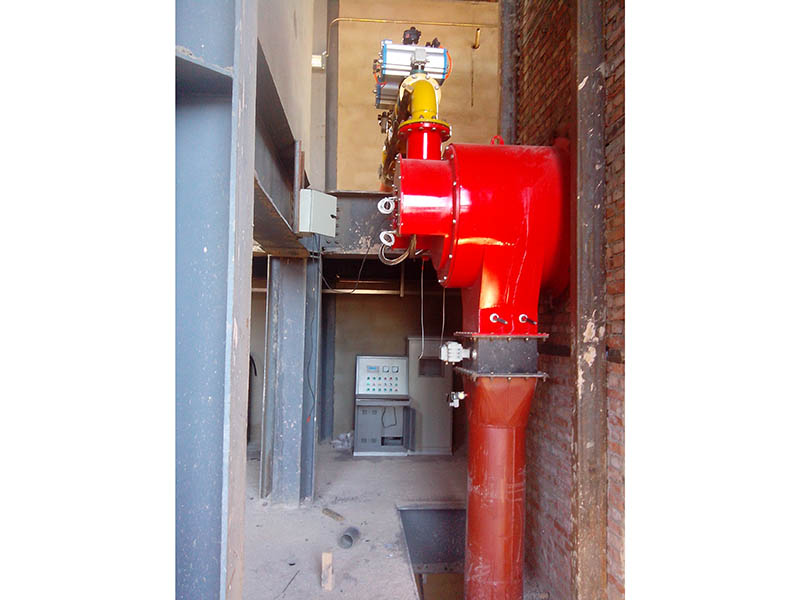

There are two kinds of natural gas burner by combustion method: Blast air burner and non-blast air burner. The internal-mixed multiheads and external-mixed multiheads are applied in the burner with safe combustion, stabilization and efficiency. Wide range of power adjusting. The different type of automatic control system can be applied according to the flame size required from the customers.

Blast air burner

The blast air burners can be divided into the electromechanical integration type and split type according to different structures of the burner. The series of burners are composed of multiple internal-mixed inside nozzle,external-mixed nozzle and air distribution duct. In order to realize complete combustion and facilitate adjustment, the air shall be divided into two parts to enter into the burner during combustion(the primary air and secondary air). The flame shape and combustion conditions shall be adjusted by adjusting the primary air and secondary air flow and air speed, to realize stable and complete combustion. It can be applicable for the high-pressure,medium-pressure and low-pressure fuel gas and the product has been obtained the National Patent.

Feature

1. The burners are compact structure,artistic appearance and convenient installation.

2. The method of combining the internal-mixed multipleheads and external-mixed multiheads are applied, to realize safe,stable and high-efficient combustion.

3. The designed pressure of the natural gas is 8-10KPa usually and it can also be designed according to the actual working conditions of the user.

4. Wide power adjustment range:30% to 110%.

5. The flame dimensions can be designed according to user’s requirements.

6. The different forms of automatic control can be configured: type (air door sectioned control and frequency conversion sectioned control), air door adjusting proportion type and frequency conversion adjusting proportion type, touch screen digital control, industrial computer frequency conversion proportion control and so on. It can meet different user's requirements.

7. The fuel gas and the air door shall be controlled by the separate channel, the air / gas proportion K value shall be set online to accurately control the air / gas proportion and prevent error caused by connecting rod transmission.

8. The system shall be equiped with flame detection, over-temperature, overpressure, leakage detection in valve groups and other safety interlock protection.

9. If the self-control system is removed, normal combustion can be conducted with manual operation, which is easy to adjust.

Non-blast burner

The non-blast burners can be divided into the non-blast burner and non-blast / blast burner according to different forms of the air distribution. The burners adopts the new design idea, which combine the traditional combustion process( the single internal mixed and the external mixed combustion), forming a new type of internal and external mixed combined non-blast fuel gas burner. The non-blast / blast burner is also the new burner which combine the non-blast combustion technology and blast combustion technology. The s burners have been obtained the National Utility Model Patent.

Till now, more than 500 sets of non-blast burners have been applied in the Jidong, Daqing, Liaohe, Dagang, Shengli, Zhongyuan, Henan, Changsheng oilfield, which stable performance, convenient operation, creating the high economic and security benefits.

Performance characteristics

1. The non-blast combustion technology is applied in the large negative pressure fuel gas furnace, heating furnace and industrial furnace. The single burner can be non-blast high-efficient combustion in the fuel gas negative pressure furnace with less than 20t/h (14MW or 1200*104kcal/h).

2. It can be realized that the stable and high-efficient combustion within the designed scope of 30% to 110% output, meeting requirements for the ulimate load.

3. Local control. It can be electricity-free self-control. With simple operation, it is applicable for outdoor operation.

4. The non-blast / blast burner can be operation with or without blast. It is wide scope of application.

5. The blast air is forced to work before the igniton in the non-blast / blast burner, to guarantee safe ignition. After the ignition is Ok and the main fire is established, the fan is stopped automatically. The air and the gas can be automatic matched by utilizing the fuel gas pressure and the negative pressure of the furnace chamber. So that the safe and high-efficient combustion is guaranteed and the ulimate energy-saving effect is reached.

6. According to the user's requirements, the fire-off protection, automatic ignition control, automatic adjustment and the interlock control system required for operation can be configured with stable performance.

7. In addition to the natural gas, the burners shall also be applicable for the semi-water gas, coke oven gas, gas and so on. The designed pressure shall be 20-50kpa.

Specifications

Introduction of the model

| One-section fire | Two-section fire | Proportion type | |

| Frequency conversion type | Type A | Type B | |

| Natural gas | Designed power | Air blast integration type (the default part is the split type) | |

| Jinsah general type burner |

Technical performance Figure

| Model | Designed power | Designed fuel gas amount | |||

| Gas compustion | Power adjusting range | Flame diameter | |||

| Flame length | Long flame | Short flame | |||

| Motor power | Note: take QDW=8500Kcal/Nm3 natural gas as an example. | ||||

| The specifications of the product can also be specially designed according to user's requirements. | |||||

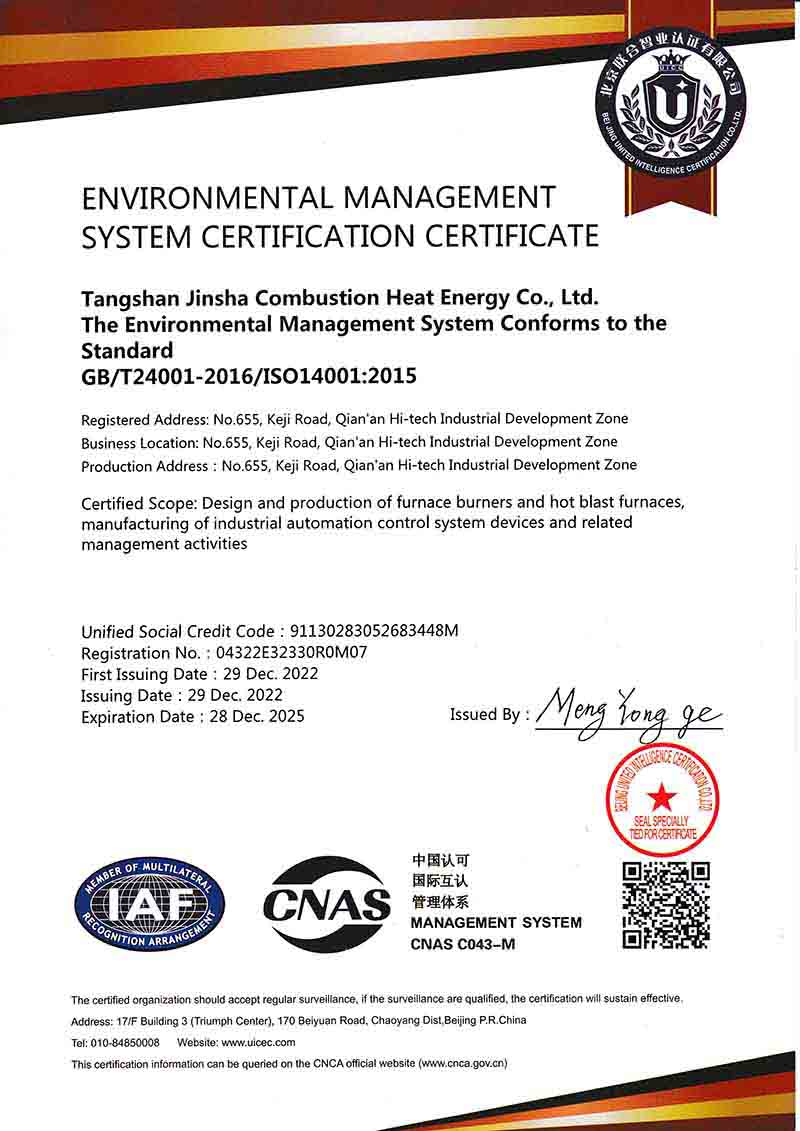

Certificates

EN

EN  CN

CN AR

AR BG

BG HR

HR CS

CS DA

DA FR

FR DE

DE EL

EL HI

HI IT

IT JA

JA KO

KO PT

PT RO

RO RU

RU ID

ID UK

UK VI

VI TH

TH TR

TR FA

FA MS

MS BE

BE HY

HY AZ

AZ KA

KA BN

BN LA

LA KK

KK UZ

UZ AM

AM KY

KY